This will be the first in a new series where we examine the armor schemes of various battleships throughout history. We will start off this series with the never-built American super dreadnoughts, the Montana class battleships. During the Montana class armor post we will examine the main features of the armor layout such as the vertical and horizontal protection as well as the torpedo defense system.

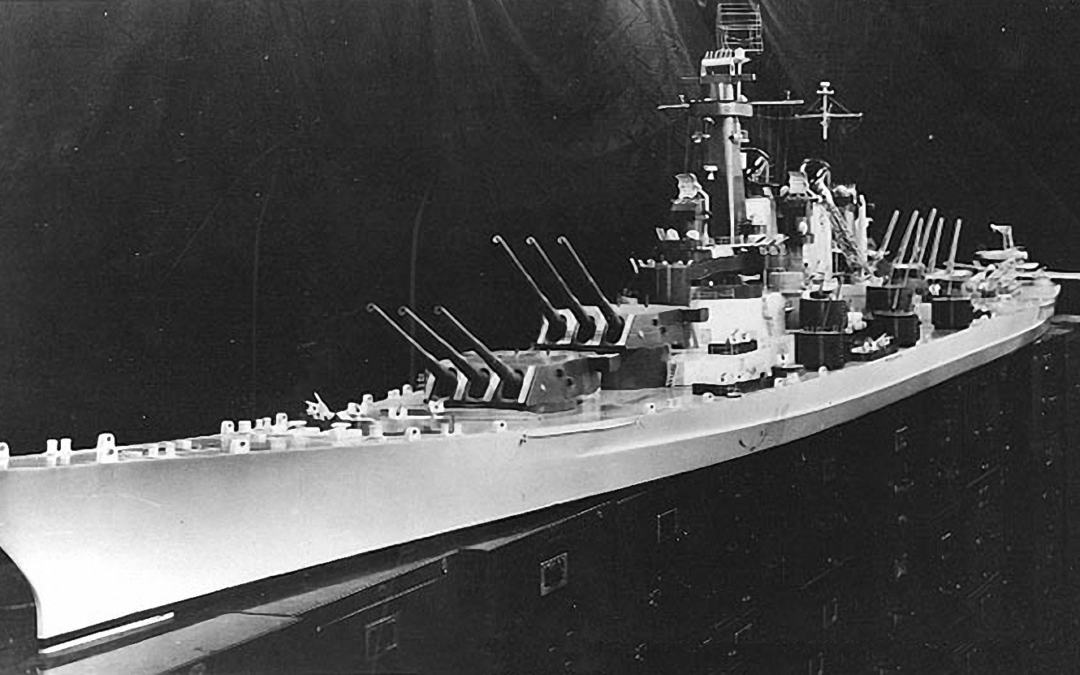

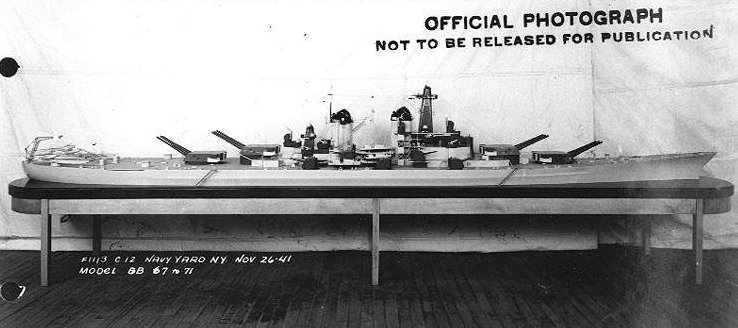

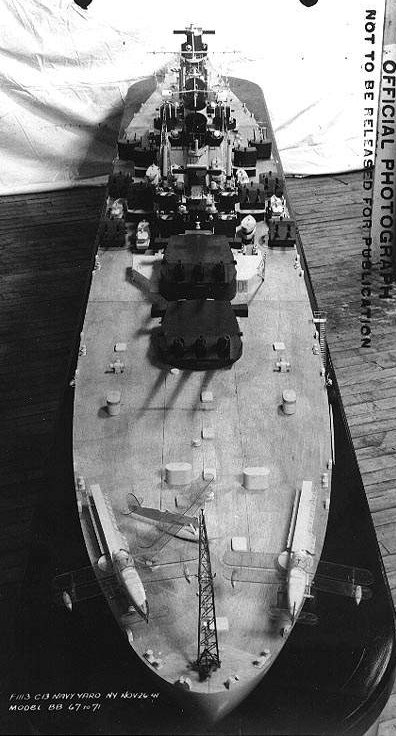

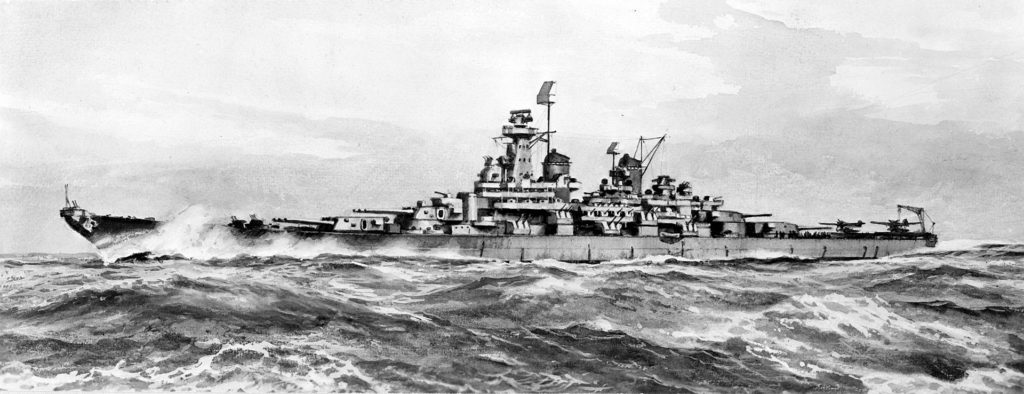

The Montana class battleships, designed but never built, would have been the largest and most powerful dreadnoughts of the United States Navy. They would have also represented the return to the heavily protected battleship designs favored by the United States Navy. With the prior Iowa class battleships, the US Navy had diverged from their preferred designs in the interest of higher speeds. The Montana class, no longer bound by tonnage restrictions or other limitations, allowed designers to incorporate newfound combat experience to produce the most protected battleship.

Montana Class Battleships : Armor Overview

Vertical Armor

The driving force behind the armor protection of the Montana class was balancing the protection of the dreadnought against the power of its own 16”/50 guns. The South Dakota and Iowa class battleships had managed to provide protection against 16” guns when firing the earlier lightweight 16” armor-piercing shells (Mark 5 – 2,240lbs). However, the introduction of heavier shells (Mark 8 – 2,700lb) greatly enhanced the firepower of the battleships, so much so that the armor was unable to withstand them. The Montana class were the first battleships to be designed using these heavier projectiles as the guideline.

Quick Note: External vs. Internal Armor Belts

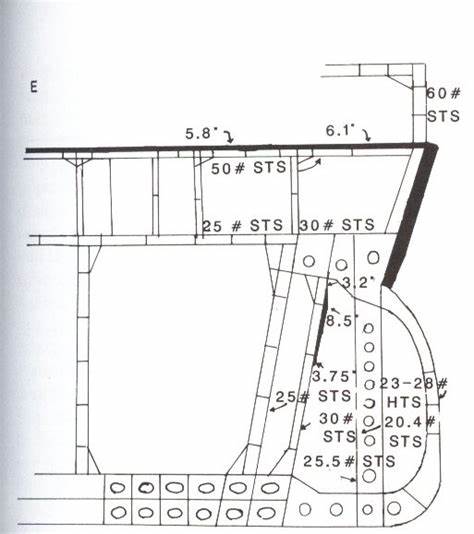

The vertical belt armor of the Montana class differed greatly from the previous South Dakota and Iowa classes. The earlier battleships utilized internal armored belts in the interest of weight savings. While effective in conserving tonnage, internal armored belts were problematic. Incoming projectiles pierce the outer hull before making contact with the armor belt. Shells along the waterline could even cause flooding regardless of whether they penetrated the armor belt. On the other hand, repairing damage to the armor belt required cutting into the hull to access it. This led to longer, costlier repair times. Reasons such as this led designers to return to the external armored belt for the Montana class.

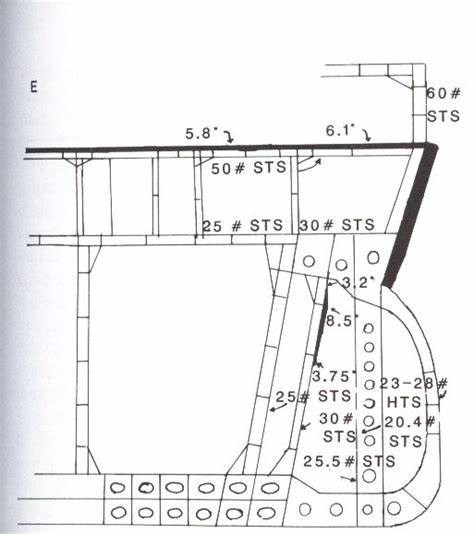

Protecting the sides of the hull against such a powerful shell required an armored belt of impressive thickness. The Montana class battleships used an armored belt of 16.1” (409mm) mounted on top of 1” of special treatment steel (25mm). Once the belt reached the waterline, it began to gradually taper down to a thickness of 10.2″ (260mm). The armored belt was further enhanced by inclining it at 19 degrees, increasing the relative armor thickness of the belt. A close ranges, the relative armor thickness would be about 459mm (18″). This would increase further as the range increased due to the steeper angle of the approaching shell.

Diving Shells

If one armor belt is good, two must be better right?

An interesting feature of the Montana class was a secondary armored belt carried behind and below the main belt. This belt was designed to counter the threat of diving shells. Diving shells are armor-piercing shells that strike the water short of the hull. Their momentum is such that they can be carried for some distance underwater, far enough to bypass the main belt by piercing the hull under it. During the interwar years, many Navies became aware of the threat of diving shells and worked on various methods to protect against them. One of the most common was continuing the belt down farther below the waterline and sometimes all the way to the bottom of the hull (South Dakota, Iowa, and Yamato class battleships all used this method).

The United States discovered through testing that one expansive armor belt was problematic. Though effective against diving shells, it had the opposite effect against underwater detonations from torpedoes or mines. The solution to this was to separate the upper and lower belts. This would be equally effective against shells or underwater explosions.

The lower belt on the Montana class was 8.5″ (216mm) over the magazines and 7.2″ (183mm) over the machinery spaces. The belt continued down to the ship’s triple bottom, tapering down to about 1″ (25mm). This lower belt was slightly inclined as well, though not to the extent of the upper belt, only being inclined at about 10 degrees. Though the system never got to go to sea, it likely would have been the most effective yet designed by the United States Navy.

Horizontal Armor

The well-protected belt of the Montana class was capped off by equally formidable deck armor. Protection was provided by no less than three layers of deck armor. Each one of these three layers of armor were intended to fulfill a specific purpose. By each fulfilling a role, it was intended that all three would, together, provide extremely comprehensive armor protection.

The first deck was the weather deck, made up of 2.25″ of armor. By itself, this layer of armor would withstand light weaponry such as strafing fighters or high explosive bombs. It would also support the main armored deck. The weather deck would trigger the arming mechanism on incoming bombs before they hit the main deck. The upper deck would also affect incoming shells in two ways. They would help decap incoming shells while also inducing a small measure of yaw upon them. This would reduce the ability of the affected shells to penetrate armor, allowing the main deck to better resist them.

Below the weather deck was the main armored deck. This was the strongest portion of deck armor at 7.05″ (180mm) thick (5.8″ of armor with 1.25″ of special treatment steel). The main armored deck would protect the citadel of the Montana class against the heaviest incoming projects including armor-piercing bombs and heavy calibre shells. It was significantly thicker than all previous designs (6″ on the Iowa class, 5″ on the North Carolina class).

The third and final layer of horizontal armor was the splinter deck. The splinter deck was intended to catch any shrapnel or spall, preventing fragments from penetrating into the vitals. The splinter deck ranged from .625″ (16mm) over the machinery spaces to a maximum of 1″ (25mm).

Altogether, the horizontal armor protection of the Montana class would have been 9.925″ (252mm) over the machinery and 10.3″ (262mm) over the magazines.

Turret Armor

Though the Montana Class would have utilized the same 16″/50 Mark 7 guns and a similar three gun turret design to the Iowa class, they would have featured greater protection here as well. Armor protection was enhanced on almost all sides.

The turrets of the Montana class would have featured turret faceplates 3″ thicker (22.5″ vs 19.5″) than those found on the Iowa class. The turret roofs would have been almost 2″ thicker (9.9″ compared to 8″) while the sides of the turrets would have been .5″ thicker (10.75″ vs. 10.25″) than the Iowa class. Only the rear plates of the turrets would have been identical, but this was only due to the fact that rear turret armor was mainly intended to counterbalance the weight of the 16″ guns.

| Turret Plates | Montana Class | Iowa Class |

| Front Plate | 18″ (457mm) Mounted atop 4.5″ (114mm) Structural Backing Steel | 17″ (432mm) Mounted atop 2.5″ (64mm) Structural Backing Steel |

| Side Plates | 10″ (254mm) Mounted atop .75″ (19mm) Structural Backing Steel | 9.5″ (241mm) Mounted atop .75″ (19mm) Structural Backing Steel |

| Rear Plates | 12″ (305mm) Mounted atop .75″ (19mm) Structural Backing Steel | 12″ (305mm) Mounted atop .75″ (19mm) Structural Backing Steel |

| Roof Plates | 9.15″ (232mm) Mounted atop .75″ (19mm) Structural Backing Steel | 7.25″ (184mm) Mounted atop .75″ (19mm) Structural Backing Steel |

The barbettes, the armored cylinders that the turrets sat on, were also thicker on the Montana class. Barbette armor for the Montana class would have ranged from 21.3″ (541mm) to 18″ (457mm). In comparison, the Iowa class barbette armor ranged from 17.3″ (439mm) to 11.6″ (295mm).

As a warship expected to slug it out with enemy battleships, the Montana class gained considerably greater protection for its main battery turrets. No battleship in the US Navy would have had their guns so well protected, allowing the Montana class battleships to continue fighting even under heavy fire.

Torpedo Defense System

During the development of the Montana class, it was becoming increasingly apparent that torpedoes and mines were becoming more lethal. At the same time, the protection of previous classes (Iowa and South Dakota classes) was found to be less than ideal ( largely due to the continuation of the main armored belt to the bottom of the hull that was mentioned earlier).

The Montana class would continue to utilize the multi-layer torpedo defense system favored by the United States. Four void spaces separated the outer hull and the innermost retaining bulkhead. The outer two void layers were liquid-filled to disrupt the blast wave and catch any shrapnel. The inner two layers were left empty (nothing but air) to allow the remaining blast wave to dissipate.

The underwater protection of the Montana class was further enhanced by the dreadnought’s greater size. A larger hull allowed for a deeper torpedo defense system. In turn, a deeper torpedo defense system provided more room for the explosion to be absorbed before it reached the vitals. The Montana class had a torpedo defense system depth of 20.5′ (6.25m) compared to 17.9′ (6.46m) of the Iowa class or 18.5′ (5.64m) for the North Carolina class. The greater beam of the Montana class also allowed them to carry their torpedo defense systems further forward and aft, providing greater protection over the magazines.

The Montana class would have been the best protected of the American dreadnoughts against underwater threats. The combination of experience and size coming together to provide a level of protection unavailable to previous battleships.

Montana Class Armor : Final Thoughts

The Montana class battleships would have been the most protected battleships ever put to sea by the United States. They would have also been among the most protected battleships of all time, rivaling the Yamato and British King George V class.

The Iowa class struggled to withstand the power of the Mark 8 Superheavy Shells, one of the most powerful armor-piercing shells of its time. They could only claim a relatively small immunity zone of 23,600 Yards to 27,400 Yards. The Montana class, specifically designed with these shells in mind, had a much greater immunity zone, one that ranged from 18,000 Yards to 31,000 Yards. This translated into an incredible level of protection against the shells used by other navies. Only the 18.1″ guns of the Japanese Yamato would have posed a serious threat. The Montana class would have been a tough opponent for an enemy battleship.

This same level of protection would have also translated well to other weapons. The thick deck armor would have presented a formidable obstacle to aircraft, requiring the heaviest armor-piercing bombs to penetrate it. The torpedo protection system would have also given the Montana class greater protection against torpedo-armed aircraft and roving submarines. Not enough to grant immunity of course, but a greater amount of protection compared to previous ships. A dreadnought designed for its environment.

Perhaps the biggest takeaway from the protection of the Montana class battleships is that so much can be achieved when a battleship is designed with a minimum of restrictions. Previous battleships had been designed while under various restrictions, whether it be gun size or tonnage. This forced United States designers to pick and choose how to invest their tonnage. Armor often was sacrificed for higher speed or more powerful guns. The Montana class presented a unique opportunity for the United States to not cut corners. With zero compromises, the Montana class could be of the size and tonnage required to carry the heaviest armor, the most guns, and still grant them respectable speed.

Further Links of Interest:

Liked This piece on the Brooklyn Class? Check out some Other Links

Want to follow Navy General Board on Social Media? Check us out on the platforms below!

- YouTube

- Want to help the site continue to expand? Support us on Patreon.

- Learn more about how NGB got started!

Some more great articles:

How the Battlecruiser HMS New Zealand was paid for

Recent Comments