Skegs are an unusual feature of warship construction. Some warships had them, others did not. Some warships buried only a few of their shafts inside of skegs, others buried all of them. This seemingly random use of skegs has made them the subject of considerable debate. Some believe that skegs were to serve as barriers against torpedo damage, helping to protect the shafts and screws. Others claim that they were to make the hull more streamlined, improving speed. Still others note that skegs were designed for structural purposes, making the hull stronger and stiffer. Turns out all of these claims are true. In this article, we will examine skegs and describe the various benefits they provided.

First and Foremost, What are Skegs?

Typically, a ship’s shaft protrudes from the hull. It is largely exposed, though it is supported by one or more support beams/struts that extend from the hull to the shaft. This arrangement was used on warships throughout history and even continues to be used on warships today.

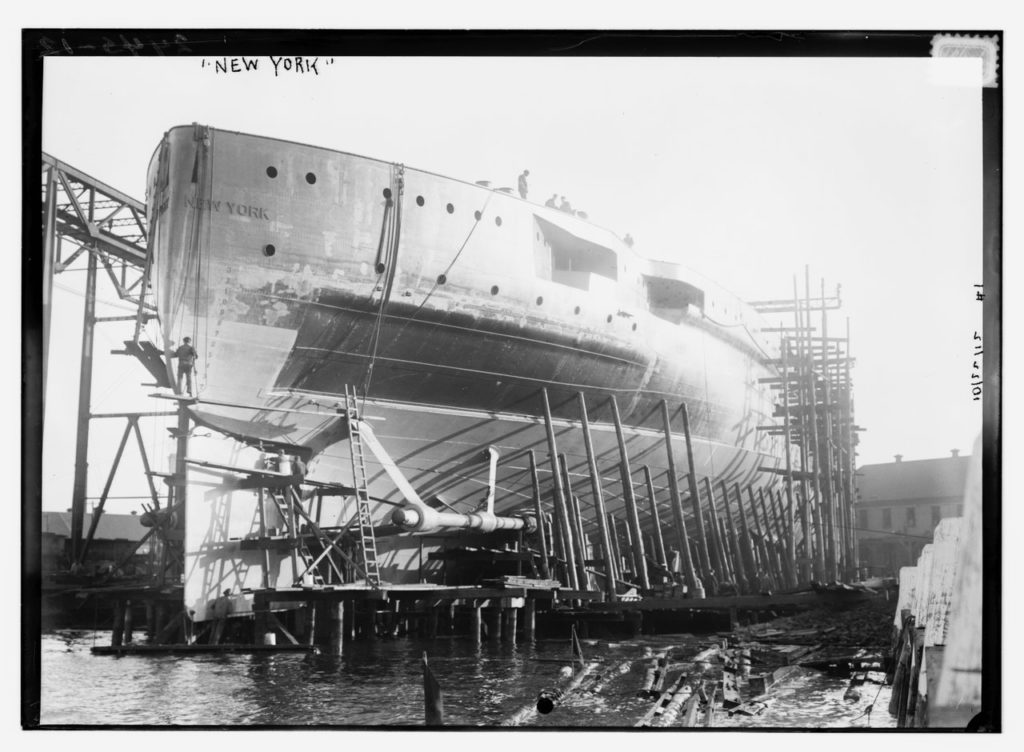

With a skeg, the shaft is contained inside of a fin-like extension of the ship’s hull. A skeg allowed the shaft to remain almost fully enclosed by the ship’s hull.

What purpose do skegs serve?

Though skegs could offer several unique benefits, they were often utilized on individual warship designs to suit a particular purpose.

Hydrodynamics

*Hydrodynamics – The study of the forces created by and acting on liquids.*

The most common use for skegs was for hydrodynamic purposes. They could help improve the flow of water along the ship’s hull. This allowed the ship to slide more easily though the water, reducing drag which helped increase speed and range (So long as it was enough to overcome parasitic drag caused by skin-friction. More on that later).

In addition to helping the efficiency of the hull, skegs could also help improve the efficiency of the ship’s screws. By improving how water flowed around the ship’s hull, skegs could help reduce the turbulence of water right before they reached the screws. A screw has more difficulty in generating thrust when it is pushing turbulent water. By reducing the turbulence of water reaching the screws, they allowed the screws to operate more efficiently.

Structural Strength

Another important attribute of skegs was that they improved the structural strength of the hull. They helped make the stern of a ship (one of its weakest sections) stronger and more resistant to outside forces. This was one of the primary reasons the last generation of American dreadnoughts featured skegs. Their hulls tended to narrow towards the stern and lacked the sternpost/keel plate/skeg that battleships such as Bismarck, Yamato, and King George V classes featured. Skegs would grant them sufficient strength and keep the aft section of the hull more rigid.

Skegs also gave the hull additional support when outside of the water. They provided more space for keel blocks when the ship was placed in drydock. This allowed the immense weight of the ship to be more evenly distributed. The German H-class battleships, specially H-41, featured the addition of a skeg on her inner shafts to provide more support for the battleships when in drydock.

Protection

On the subject of protection, skegs did offer several benefits. Due to the greater structural strength, they did reinforce the stern, structurally one of the weakest , most vulnerable parts of a warship’s hull. This could potentially help the ship better resist the force of underwater explosions from mines or torpedoes.

Though never fully put to the test, skegs could also theoretically act as a additional level of protection for the ship as well. A skeg could act as a barrier, shielding the screws, shafts, and rudders inboard of the hit by absorbing the blast of an underwater explosion. This would most likely destroy the skeg and shaft that was hit, but if it protects the other components behind it, then the warship has a better chance of retaining its maneuverability.

In addition to acting as a shield, the extra support provided by a skeg to the shaft might have offered an additional form of protection. The loss of HMS Prince of Wales was the result of uncontrollable flooding due to her outer port shaft being damaged by a torpedo. The shaft spun wildly and ruptured the water tight barriers around it. This allowed over 2000 tons of water to enter the ship through the shaft. It is possible that skegs might prevent such an incident from occurring by better securing the shaft in place.

Disadvantages to Skegs

With all of these benefits that skegs can offer, it might lead one to question why they were not used for every new design of warship. This is due to the fact that they can negatively impact performance. Due to the fact that they are extensions of the hull and that water flows over them, larger skegs can reduce efficiency by causing excessive skin friction drag. Testing of the American Montana class showed that skegs did often create some form of drag regardless of the design or size.

Not only does this reduce performance, it can also lead to other issues. One of the most common being vibration issues. On the North Carolina class dreadnoughts, excessive vibration issues were discovered due to the effect of the skegs on the movement of water around the hull. Due to the skegs being components of the hull, they could not be removed and the solution was to utilize different screw configurations to lessen the issue. Though vibration was reduced, it was never fully eliminated.

Final Thoughts

Overall, the use of skegs offered several benefits when used effectively. However, they were not a simple upgrade that could be easily retrofitted onto just any hull. As a crucial component of the hull, a skeg had to be carefully designed and precisely placed. If successful they were highly beneficial, however they also had the potential to be a liability. For this reason, skegs were, and still are, used sparingly in warship design.

Further Links

Want to follow Navy General Board on Social Media? Check us out on the platforms below!

Help the Website grow by purchasing a Navy General Board Shirt!

- YouTube

- The Navy General Board Forum

- Want to help the site continue to expand? Support us on Patreon.

- Learn more about how NGB got started!

More Great Articles

Check out our collection of articles. Some of our latest articles include:

The USS Midway and her Greatest Carrier Landing

Life aboard a US Navy Battleship During the Korean War.

The Bayern Class vs. the Queen Elizabeth Class

The Malta Class: The Carriers that Never Were

The Last Naval Battle of World War II

Check out Awesome Guest Articles!

Recent Comments